Application : Cement Plant Clinker Grinding Unit, Steel Mill

Annual Output : 200,000-1,000,000 tons

Power Consumption : 35-45 kWh/t

Blaine Fineness : 4200-4500 cm²/g

As a new type of high performance concrete admixture, slag (slag product applications) powder has all kinds of performance advantages about improving concrete compressive resistance, tensile resistance, sheared resistance and bended resistance. At present, with the same amount of slag powder instead of concrete and cement product of cement dosage, which has become the main trend of building materials industry. The Great Wall machinery is a professional supplier of slag powder production line, can provide "turnkey" service from civil engineering to debugging and capacity and standard reaching to customers, let customers put into production of mineral powder with saving worry, saving effort and high-efficiency.

1. A good return on investment, can recover the cost-effective

With the application widely of mineral powder, the domestic market demand increase rapidly in this project. Investment powder production line with considerable economic benefit and high return on investment, usually 1-3 years can recover the cost.

2. High efficiency, energy saving, environmentally friendly

GRMS series slag vertical mill can reduce power consumption effectively in the process of production as the core equipment of production line. Meanwhile, because it is a negative pressure operation, vertical mill produces almost no dust during operation, low noise and pollution than traditional tube mill.

3. Mature general contrasting scheme

Chaeng has the domestic first-class technical team, and combined with domestic chief vertical expert for technology. Great Wall Machinery can design detail general scheme according to customer's actual situation, and can provide "turnkey service" from civil engineering to production operation.

4. The customers case witness all over the country.

Chaeng GGBS production line has been recognized by key customers, the domestic production operation of the production line has been up to more than 30, customers all over the country.

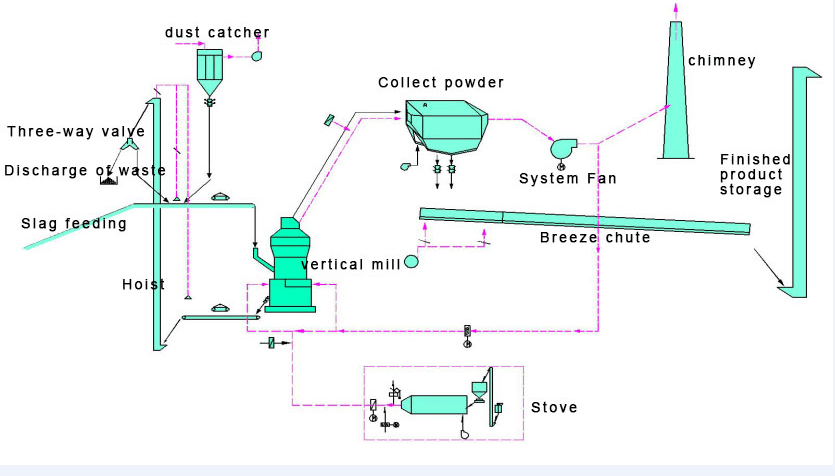

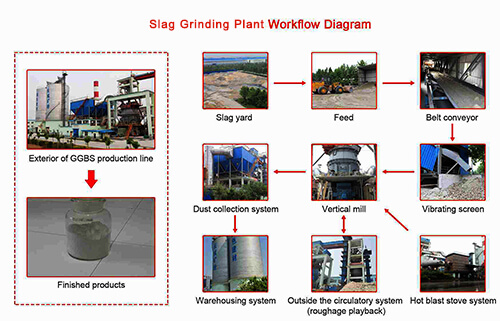

The stacked slag is packed and feed by the forklift trucks, then transported by belt conveyor. During transmission, the slag will pass through the iron separator and vibrating screen, then through the weighing equipment and elevator, and finally come into the vertical roller mill.slag will come through the powder selector and be dried with the hot air form air heating furnace after grinding. Slag that meets the fineness requirement will pass through the separator, then delivered by air blower and elevator, and finally come to the storage silo.

|

Output (t/a)

|

Model of Vertical Roller Mill

|

Capacity (t/h)

|

Mill Power Consumption (kWh/t)

|

Grinding System Power Consumption (kWh/t)

|

Coal Consumption (kg/t)

|

|

200,000

|

GRMS26.21

|

30

|

32

|

|

|

|

300,000

|

GRMS33.31

|

50

|

30

|

42

|

18

|

|

450,000

|

GRMS40.41

|

70

|

30

|

|

18

|

|

600,000

|

GRMS46.41

|

105

|

28.5

|

37

|

18

|

|

1,000,000

|

GRMS53.41

|

160

|

26.5

|

35

|

17

|