Raw mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries.

Raw material mill, also called raw meal mill, is important grinding equipment in cement production process. After being crushed, the raw meal enters the raw material mill. The raw meal is grinded into fine powder by the motion and squeezing of steel balls. The raw material mill manufactured by Great Wall Machinery can meet the raw material supply of 250~2500t/d cement production line.

1. less investment and quick benefit

Being a kind of very mature mill, raw material mill is widely used in cement industry. It is cheap and suitable for cement plant with less investment to put into production very soon.

2. special streamline design

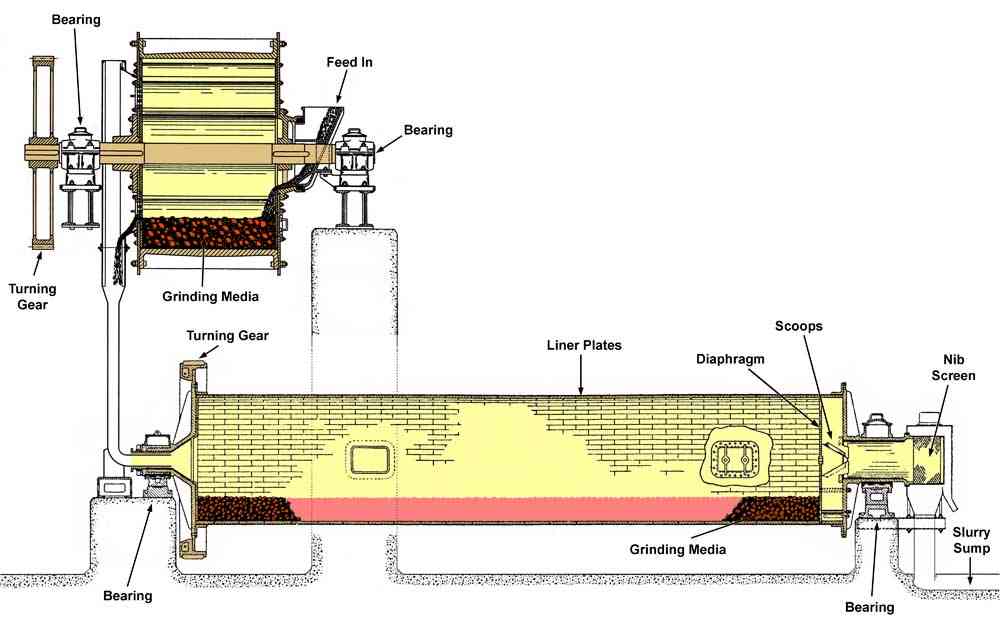

The big end cover and discharge system of the raw material mill adopt special streamline design, which reduces the air resistance and increases the effective volume, so it is easy to discharge and the yield of raw meal improves.

3. more effective structural design

The raw material mill is single-chamber, and the liner in the mill adopts modular design, using different liner structures at different stages of the mill, so the grinding efficiency improves significantly.

4. free and flexible working manner

The raw material mill can adopt edge drive or center drive according to different models, so the configuration is very flexible. It can not only be used to dry process production, but also can be used to wet process production. It can also grind and stove the materials simultaneously.

The raw material mill usually adopts two ways: edge drive and center drive. The materials enter the mill continuously and evenly through the feeder, and the motor drives the cylinder to rotate via the reducer. Firstly, the materials enter the first cabin spirally through the hollow shaft. Due to the rotation of the cylinder, frictional force and centrifugal force generate between steel balls and materials and cylinder. Under the effect of centrifugal force, the materials are brought to a certain height, and the materials scatter and drop in a material curtain form, then struck and grinded by steel balls. The sorting equipment selects qualified materials from the grinded finished product, and in the circulation grinding system, the unqualified materials are sent back to the mill and struck and grinded by the grinding media until the fineness is qualified.

The classifying liner improves the grinding efficiency.

There is wear-resistant liner in the cylinder and have strong wear resistance.

The double sliding belt structure is adopted, increasing the stability and running time of the equipment.

Simple structure, convenient operation and strong adaptability make it can produce continuously in short time.

The advanced partition for powder selecting and discharge grate greatly improves the efficiency of grinding and selecting.

The gap between the bearing cage of sliding belt and the base is sealed with rubber and sealant. While working, the seal is strengthen to prevent the oil from leaking.