Raw material: limestone

Capacity: 300-1000t/d

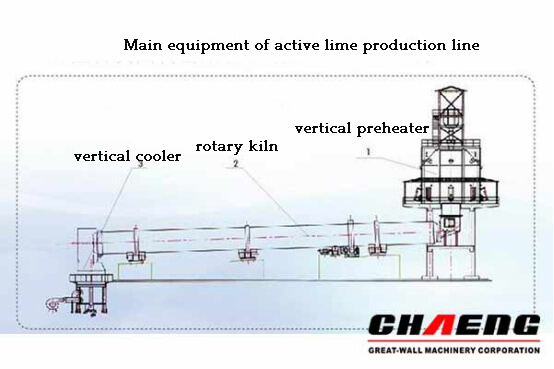

Equipment configuration: lime rotary kiln + vertical preheater + vertical cooler

Active lime is one of the most important auxiliary raw material for steel making, and it can improve the quality of the liquid steel, increase output, decrease the steel making consumption and stabilize operation, and can remarkably promote the beneficial efficiency of enterprises. As a director unit of China Lime Association, Xinxiang Great Wall can according to client’s requirement, provide clients with EPC services from scientific research report, design, equipment, civil engineering, installation, commissioning to reaching designed standard and output.

Grate bar and discharge device for big block

Cooling chamber lower the cooler

Support Device

1. Body

2. Riding wheel

3. Gear ring

4. Tire

5. Transmission device

Upper feeding system: upper material bin, feeding chute

Preheater body: preheater chamber, suspension device

Stacker device: stacker part, frame, connecting rod.

Hydraulic system

1. High activity, and good quality: the activity of the finished product can reach 360ml, underfiring and overburning rate <8%,and the quality is uniform.

2. Advanced technology, energy conservation and environment protection: advanced calcination technology, low energy consumption; temperature of discharged fuel gas < 220℃, which is good for dust collection, and can fully meet the requirements of energy conservation and environment protection;

3. Large output. The maximum capacity for a single line can be 1000t/d.

4. High degree of automation, and easy operation. Adopt DCS remote control system with high degree of automation.

| Designed capacity (T/D) | 200 | 300 | 400 | 600 | 800 | 1000 | |

|---|---|---|---|---|---|---|---|

| Product | active lime | active lime | active lime | active lime | active lime | active lime | |

| Preheater | specifications | RS-6.5×3.4 | RS-7.5×3.4 | RS-8.5×3.4 | RS-10.×3.4 | RS-10.8×3.4 | RS-13.5×3.4 |

| Number of push rod | 6 | 8 | 10 | 12 | 16 | 18 | |

| Kiln | specifications | φ2.8×42M | φ3.3×50M | φ3.6×56M | φ4×60M | φ4.3×66M | φ4.8×68M |

| Effective volume (m³) | 190 | 292 | 430 | 575 | 738 | 1005 | |

| speed (r/min) | 0.45-2.22 | 0.2-1.9 | 0.22-1.57 | 0.48-1.57 | 0.21-1.57 | 0.19-1.98 | |

| Cooler | specifications | LS-3×3 | LS-3.6×3.6 | LS-3.8×3.8 | LS-4.1×4.1 | LS-4.7×4.7 | LS-5.2×5.2 |

| Feed temperature | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | |

| Discharge temperature | <100℃ | <100℃ | <100℃ | <100℃ | <100℃ | <100℃ | |

| Weight(T) | 35 | 40 | 50 | ||||

| Heat rate (KJ/Kg) | 5200 | 5200 | 5100 | 5000 | 5000 | 5000 | |

| Activity (50g,4NHCL,10MIN) | ≥360ML | ≥360ML | ≥360ML | ≥360ML | ≥360ML | ≥360ML | |