Application: Cement Plant Thermal Power Plant

Annual Output : 150,000-750,000 tons

Process Type : New Dry Process

Blaine Fineness : 3300-3800 cm²/g

Cement production line is the production line construction project composed by a series of corollary equipments which are used for product cement.Our Satisfied Customer Return Ratio with the support of our skilled Cement Plant expert we are successfully installing cement plants in India, Middle Asia ,South America and South African countries.Great wall supply process design、civil construction、complete equipment、installation and trial run、technical services、the general contracting. Our complete production line are: 6000t/d cement production line、5000t/d cement production line、3000t/d cement production line、2500t/d cement production line, 1500t/d cement production line、500t/d cement production line、300 t/d cement production line construction.

As a leading cement plant Manufacturer Great Wall Machinery Co.,LTD offer all type of quality Turnkey Cement Plants, set up machineries, cement plant equipments, heavy industries setup and fertilizer plants. besides cement plants we also known for industrial gears supplier and equipments manufacturers like ball mills, rotary kilns, belt conveyors,vertical mill and other material handling equipments for cement plants equipments ect.

We manufacturing all type of Material Handling Equipments and Storage Units for the Cement Plants like: Bucket Elevators, Conveyors, Gate and Air Sliders and complete packaging units. We also provide maintenance services for existing cement plants in all over The World.

1.Timely And Fast Delivery

1.Timely And Fast Delivery

Chaeng Machinery is equipped with large steel foundry and machining workshop, which ensure the fast and high-quality production of the related equipment of cement production line. Besides, the goods are delivered in time, reducing time costs of customers.

2. Excellent Service

The company provides all-round service to customers, including project design, operation training, roller surfacing, millstone maintenance, technical support and so on, making customers use our products safely and produce efficiently.

3. Mature General Contracting Project

The company has a domestic first-rate technical team, and cooperates with domestic chief vertical roller mill experts. The company can design detailed general contracting project according to the actual situation of customers, and provide one-stop turnkey service from building projects to production and operation.

4. Advanced Dry Process Cement Production Technology

The cement production line launched by the company adopts the well-received new dry process cement preparation technology, which reduces heat consumption effectively, reducing production costs and improving the benefit.

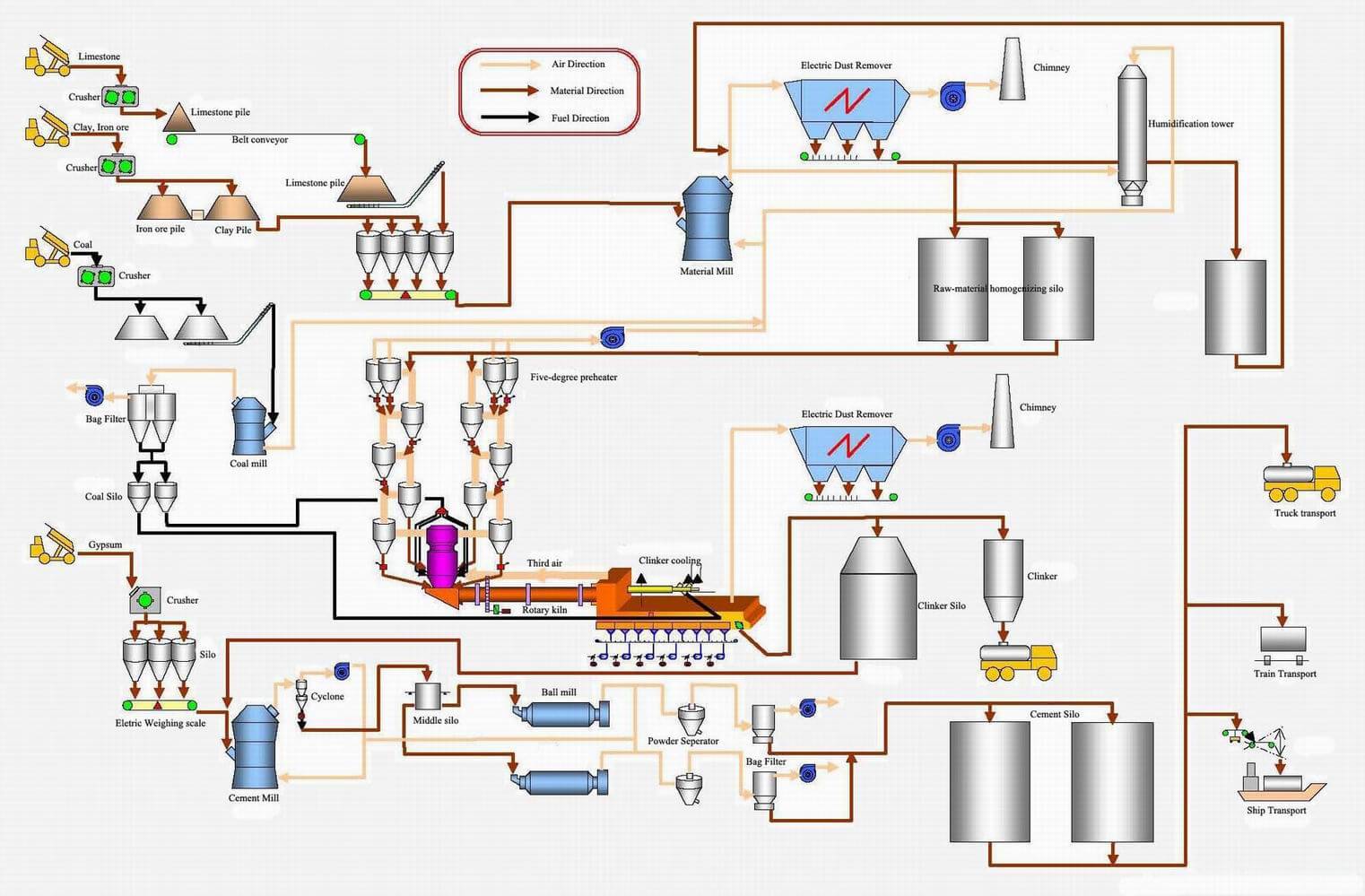

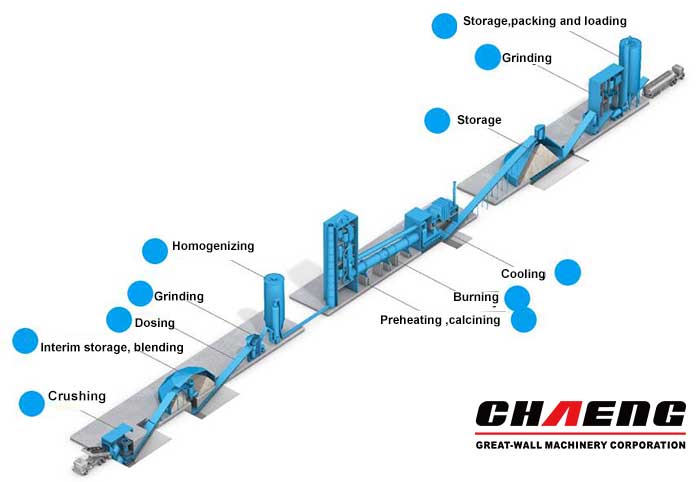

1.Crushing: during the process of cement production, most of the raw materials need to be crushed. Limestone is the largest amount raw material for cement production, so the limestone crushing has an important position at the material crushing in cement plants.

2.Pre-homogenization: Raw material pre-homogenization technology is achieving the raw material initial homogenize by scientific stacker and reclaimer technology during the storage and reclaimer process of raw materials, ensure that the raw material ground has the capability of storage and homogenize.

3.Raw materials homogenize: At the dry process of cement production, stabilize the raw material ingredient is the premise of clinker sintering, raw material homogenize system is used for stabilize the raw material ingredient inlet the kiln.

4.Preheat and decomposition: We use the preheater to finish the raw materials preheat, replace part of the capabilities of rotary kiln and reduce the length of rotary kiln. The materials finished heat gas exchanging inside the rotary kiln under the state of suspend and preheat.

5.The right of gas-solid separation: When the airflow with material powder get into cyclone, and were forced to do rotate flowing at the annulus space between cyclone barrel and inside barrel while doing downward movement.

6.The precalcining: Great wall precalciner technology is a technological leap of cement calcination process. It is added between the preheater and calciner kiln using kiln tail rise flue, set the fuel injected device, so that the process of carbonate endothermic exothermic decomposition of the fuel combustion process and raw materials, in the decomposition furnace to the suspended or fluidized state quickly, so that the decomposition rate of kiln feed is increased to 90%.

7.Sintering: After completion preheater and precalciner, next process is carried out into the clinker kiln firing. The carbonate rapidly resolved and occur a series of solid-phase reaction in rotary kiln to bring the mineral into. As the material temperature close, the liquid will become minerals dissolved in the liquid phase reaction and generates a large number. After the clinker burning, the temperature began to decrease. Finally, the cement/clinker cooler unloading the kiln cooler temperatures to the downstream transport, storage libraries and cement mill can withstand the temperatures of hot clinker while recovering sensible heat, improving system thermal efficiency and clinker quality.