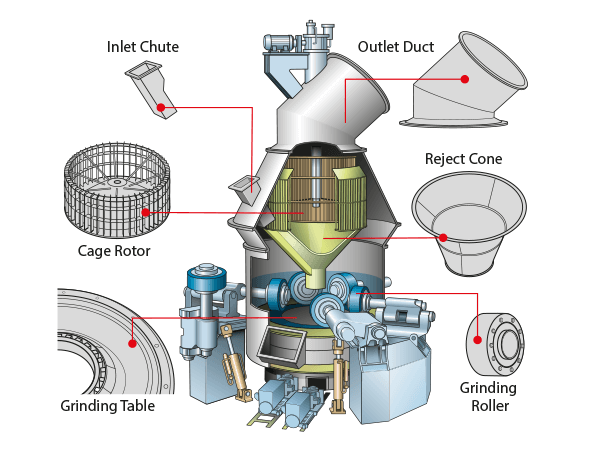

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materials.

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materials.

1. Conform to national policy requirements

1. Conform to national policy requirements

The NDRC of cement industry development policy pointed out that the cement enterprise with low output, high power consumption, high pollution will be shut down, encouraging adopt advanced technology and equipment, large-scale production.

2. Reducing the power consumption of the raw material preparation effectively

According to the display of material production measured data, it can be saving electricity above 30% use of vertical roller mill production per ton raw material than traditional ball mill, and power saving effect is very remarkable.

3. Using the most wear-resisting material to overlaying with a long service life.

The lining board and rollers jointing with the German import Boehler welding stick, has characteristics of powerful wear-resisting, corrosion resistance, heat-resistance, and can reduce operating cost and improve service life.

4. The biggest home-made raw material vertical roller mill

The Great Wall machinery production of independent research and development GRMR63.61 vertical roller mill which is the biggest home-made raw material vertical roller mill, millstone effective diameter up to 6.3m, the quantity of roller is 6, and it can improve the powder milling efficiency greatly.

The material through the feed tube fell into the center of grinding plate, and then the materials outwards the surrounding area of grinding plate at centrifugal force, to forms a certain thick layer of materials bed, at the same time material was crushed by number of rollers. The materials continuous moving to the outer edge of the grinding plate, off the grinding plate materials rising with the hot air which enter from wind ring into the vertical roller mill, through the vertical roller mill shell into the middle of the separator, in this course materials and hot gas got a fully heat exchange, the water quickly evaporates. Separator controls the finished product output size, greater than the specified size are separated and fall back to the plate, while meet the fineness demands are brought through the separator into the finished product warehouse.

CHAENG provides customers with a full range of services:

1. Design: Send a professional team to inspect the production line, and determine the appropriate vertical mill model and specifications;

2. Manufacture: CHAENG has its own large casting base, can ensure the quality of equipment and accessories, such as: vertical mill grinding table, vertical mill grinding roller, rocker arm etc.;

3, Maintenance: CHAENG can provide customers with maintenance service for vertical mill host machine, surfacing repair for grinding roller and grinding table, and parts replacement, etc., online warranty service model is convenient and quick.

What’s more, CHAENG provides customers with a full range of services from raw materials testing, program design, equipment production, installation and commissioning, induction training, etc