Full name: fully automatic mechanized coal burning vertical steel-shell lime kiln

Kiln type: vertical cylindrical

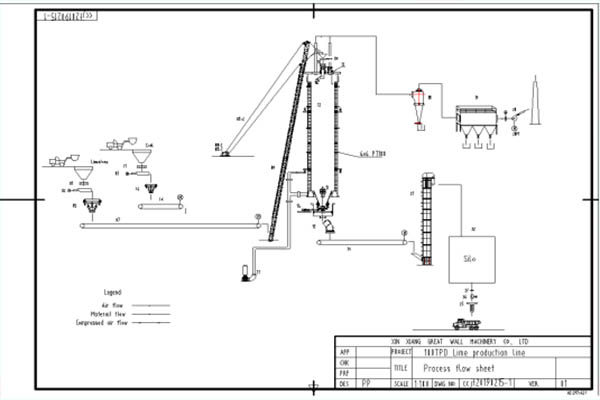

Limestone and coal are respectively fed into the storage bins by forklift. The lower parts of the bins have automatic weighing hoppers. After weighing according to the amount set by the computer, the limestone and coal are mixed. The mixed material is lifted by the skip car through the inclined bridge to the top of the kiln, and then is evenly sprinkled into the kiln through the loading equipment and the feeding equipment.

The raw material descends under the action of its own gravity in the lime kiln. At the bottom of the kiln, a roots blower cools the lime at the bottom of the kiln. The wind from the bottom exchanges heat with the lime and enters the calcining zone as fuel after its temperature reaches 600 degrees.

The Limestone from the kiln top passes the preheating zone, the calcining zone, and the cooling zone, and complete chemical reaction under the action of high temperature to decompose into calcium oxide (lime). After that, it is discharged from the kiln bottom by the disc ashing machine and the ash discharging device with the function of sealed discharge, to realize the non-stop wind unloading.

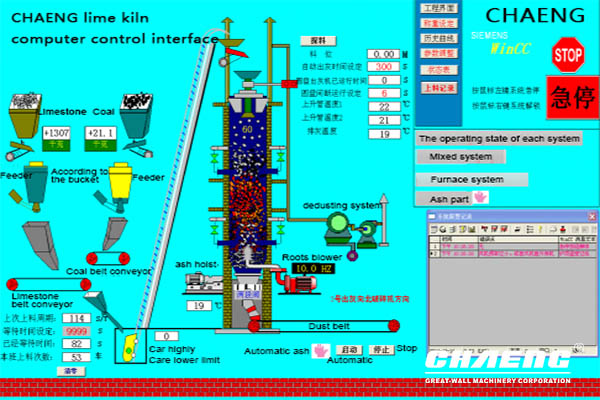

(1) computer control interface

(2) Process flow chart:

(3) Indicator parameters of production line

Limestone grain size: 40-80mm (The raw material >80mm can not exceed 5%, <40mm can not exceed 5%)

Fuel: available solid fuels such as coke, bituminous coal, anthracite, briquette. Grain size: 20-40mm for the best

Finished products can be used in metallurgy, construction, agriculture, calcium carbide, environmental protection and chemical industries.

| Indicator parameters of production line | ||||

| No. | Index | Unit | Value | Remarks |

| 1 | Effective volume of the kiln | m3 | 100-300 | |

| 2 | Effective height of the kiln | m | 15-26 | |

| 3 | Effective inner diameter of the kiln | m | 2.5-4.5 | |

| 4 | Utilization factor of the kiln | t/d*m3 | 0.7-1.1 | |

| 5 | Calendar work rate | % | <97 | |

| 6 | Daily output | t/d | 100-300 | |

| 7 | Overburning rate of lime | % | 5-12% | |

| 8 | Limestone consumption | t*limestone/t*lime | 1.78 | |

| 9 | Fuel consumption | KJ*kg lime | <4600 | |

| 10 | Power consumption | KWH/t*lime | <15 | |

| 11 | Exhaust gas temperature | ℃ | <180 | |

| 12 | Finished lime temperature | ℃ | <80 | |

| 13 | Exhaust gas concentration | Mg/Nm3 | <50 | |

| 14 | Co2 concentration in exhaust gas | % | 30-42% | |