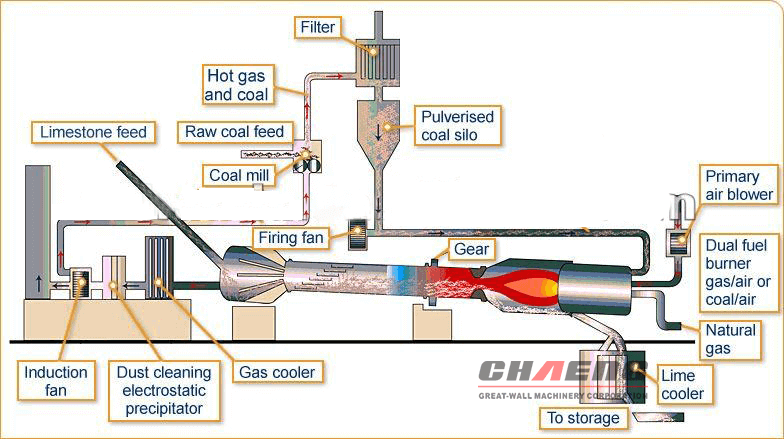

Lime rotary kiln is the main equipment of lime production line. It is widely used for many industries like metallurgy, chemical industry, building refractory materials, environmental protection, etc.

The material heated evenly in the revolving lime rotary kiln, the probability of mild and excessive calcination is low. The lime activity degrees produce by lime rotary kiln is higher than the shaft kiln. The lime activity can reach up to 400ml.

Comparison of Lime Kilns on the Market

|

Kiln type

Parameter

|

Great Wall kilns

|

shaft kilns

|

earth kilns

|

|

Capacity(t/d)

|

200-1200

|

50-300

|

10-70

|

|

Raw material granularity

|

15-50mm

|

40-80mm

|

70-250mm

|

|

Standard coal consumption

|

≥180kg/t

|

120-145 kg/t

|

200-300 kg/t

|

|

Lime activity

|

330-400ml(The influence of fuel ash and sulfur content increase on lime activity is not obvious)

|

260-300ml(the increase of fuel ash and sulfur content significantly reduce lime activity)

|

200-240ml(the increase of fuel ash and sulfur content significantly reduce lime activity)

|

|

Ignition loss

|

less than5%

|

about 10%

|

20%

|

The lime kilns produced by Great Wall Machinery have large capacity, the output can reach to 1500t/d, operating well to guarantee enterprise up-scaling and reduce the production cost.

Auto-control by using DCS remote control system, only need 2-3 operating personnel in the whole line.

Product quality is uniform, the probability of mild and excessive calcination less than 8%.

Great Wall lime kiln belongs to open type calcination equipment with advanced manufacturing technique,lower energy consumption than the old lime kiln calcination system and more environmental protection for adopts the exhaust blast furnace gas.

Since the factory established in 1958, Xinxiang Great Wall gain hundreds of loyal customers’ recognition in the sales chain for ball mill, veritical roller mill, rotary kiln. And Xinxiang Great Wall established strategic partnership with Shanghai Baosteel, FLSmidth, Arcelor Mittal, Pohang Iron and Steel Co. Ltd(POSCO), Umicore etc.

With more than half a century of research and development production experience, on-the-spot guidance for more than one hundred client, Today, Xinxiang Great Wall is fully able to provide customers from the scheme design, equipment selection, processing and manufacturing to installation, commissioning, technical training, and finally reach output and standard. That is to say, Xinxiang Great Wall has achieved the magnificent transformation from single equipment manufacturing to system solutions service.

Supply customers with “Secure choices, Easy operation, Satisfactory service” is the constant purpose of Xinxiang Great Wall for more than half a century. Equipment maintenance, spare parts supply, customers pay a return visit, perfect service and high-quality products make Xinxiang Great Wall stands in front ranks in the field of large equipment manufacturing and become numerous grinding enterprises’ common choice.