The girth gear is the major component used in rotary kiln and ball grinding mill which is required to be operated in a long time. So, the quality requirements during the actual production for the big gear ring are very high.

1. The particular heat treatment technology is used for the big gear ring manufactured by Xinxiang Great Wall Machinery which makes the improvement in the structure optimization and the hardness of the product. The performance of wear-resistant and anti-impacting are also enhanced greatly.

2. The high strength steel was used by us in manufacturing the big gear ring. We also take the optimization for the product against the operation characteristics of the rotary kiln to ensure the stability of the component during the long time operation and extend the service life of the component.

3. Our company has rich production capability in steel castings. For the components such as the girth gear ring, we can provide them in large production quantity with short cast period and large amount.

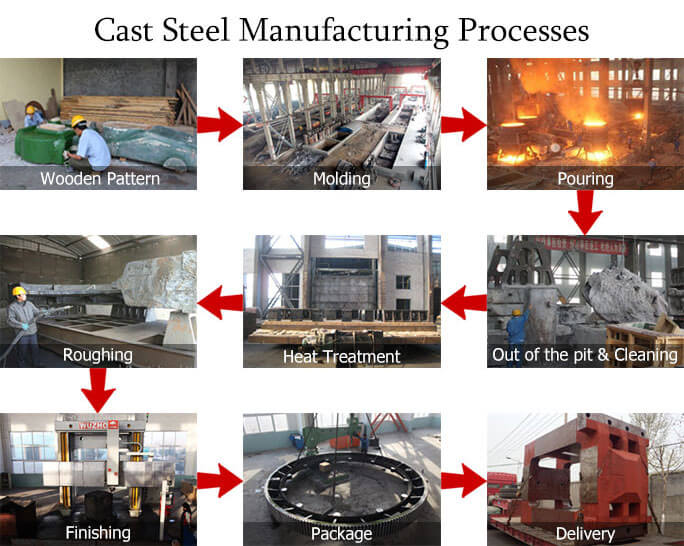

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

From day one, GREAT WALL Machinery has been seeking win-win solutions together with our customers by creating an extensive service network.

At the core of our service system is a professional team that delivers standard, high-efficiency, and consistently good-quality services. Presently, our service network covers Central China, East China, Southern China, Northern China, and Northwestern China, among various other regions. As our sale is still on the increase, we take steps to improve our after-sales service system. At the moment, we are expanding our service area beyond China to countries all over the world.