News Date:2019-11-06 14:05:50

Ball mill, also called tube mill, is important grinding equipment in cement production process. After being crushed, the raw meal enters the raw material mill. The raw meal is grinded into fine powder by the motion and squeezing of steel balls. The raw material mill manufactured by chaeng can meet the raw material supply of 300~3000t/d cement production line.

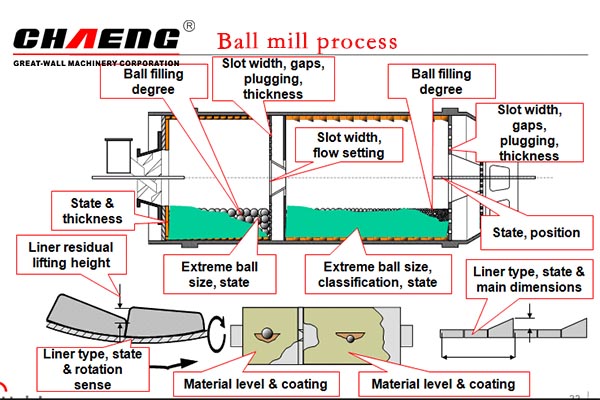

-Shell Liner Thickness Ball Charge Remarks – sizes, shape, contamination, breakages

-Shell Liner Lifter Thickness Ball Coating Remarks

-Shell Liner Remarks – crack, gaps…. Ball Classification Remarks

-Inlet Head Liner Thickness Discharge Grate Slot Size-Average

-Inlet Head Liner Remarks Discharge Grate Slot Size-Maximum

-Inlet Opening Remarks Discharge Grate Metal Thickness – gaps etc.

-Height Liner, to Balls – Average

-Discharge Grate Percent Blinded

-Width Across Balls – Average

-Discharge/Centre Screen Percent Blinded

-Calculated Percent Fill – mill ran out Height of Material relative to media

-Build up on water injection lance Calculated Percent Fill

– mill crash stopped

-Presence of material nibs