News Date:2017-04-17 15:20:29

Feature: Material: steel, self-smelting according to standard: ASTM, EN, DIN,ISO, JIS, GB, etc;

Sand mold casting: Steel casting, through sodium silicated-bonded sand and/or resin sand;

Pattern: new natural wooden mold;

Non-destructive examination:

-visual detection ;

-Ultrasonic test ;

-Magnetic particle inspection ;

Quality inspection:

-Chemical analysis;

-Mechanical performance;

-Dimension report;

Cast Tolerance: unless otherwise ASTM, EN, DIN,ISO, JIS, GB

Machining tolerance: unless otherwise according to dwg. requirement;

Product Parameter:

Material: DIN 17182 GS-16Mn5 1.1131

Fact cubage: 22 CBM

Appro.Net Wt.: 10 -100 t

Product application: slag pot in steel works

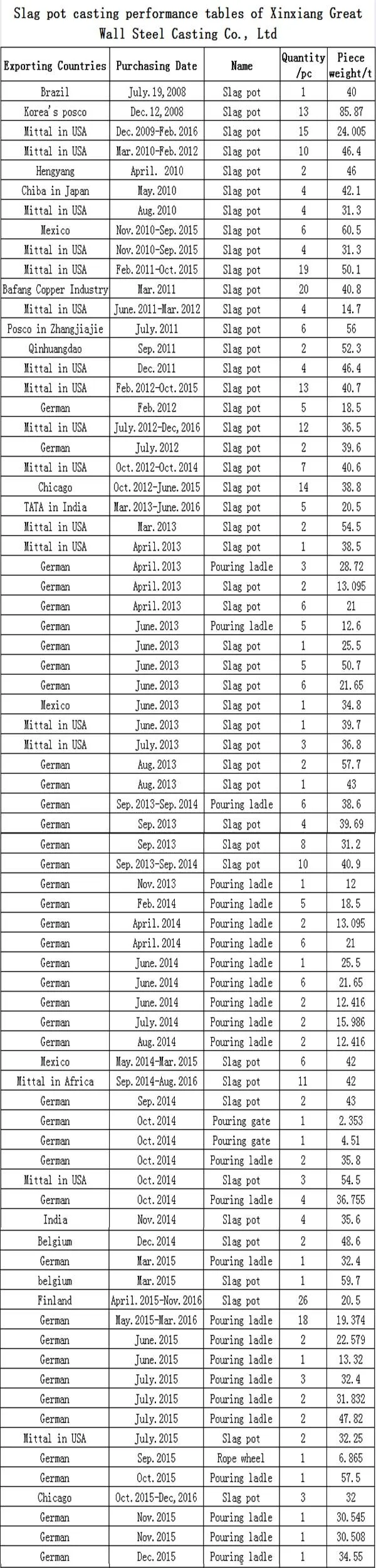

10-85 tons cast iron ladles making process is important device in steel making. It is a load-bearing device to collect molten or solid slag generated during metallurgical or chemical processes. It is a bowl-shaped container with lifting lugs at both sides. A grilling is installed inside the pot, under at least 300mm of the upper surface and divides the inner pot into some pieces. The slag pot that purchased by metallurgical enterprises generally is made by traditional cast process with long manufacturing cycle, short service life, and great scrapped quantity. Xinxiang Great Wall Steel Casting Co., Ltd, through continuous technical innovation in produce process, the slag pot has more advantages such as short cast period, long service life and strong resistance to deformation.

Except the supply of the forgings for trunnions and the engineering of the pattern, all further operations are carried-out at the in-house foundry plant.

• Moulding

Sand moulding.

• Trunnions

The trunnions - when any - are preferably cast-in: they are as a rule manufactured from the steel material S355 J2G3 to DIN EN 10250-2.

• Melting

The melting is carried out in the oxygen steel plant; the ladle capacity allows a continuous bottom pouring process the speed of which is permanently controlled. The metal analysis is checked by using a computer linked spectrograph.

• Heat treatment

- Heating to a temperature above AR3, austenitising at about 915°C and controlled cooling in furnace

- Intermediate holding at 600°C - 630°C and completion of cooling in furnace down to 300°C

• Fettling and dressing

The inner surface is processed fit-for-purpose so that the surface discontinuities - which might cause some sticking of the slag - are extensively removed. Additionally, the castings are descaled by shotblasting and the outside is additionally coated for transportation

We are manufacturer ,so you can buy from our factory directly.You can control delivery time, control quality based on competitive price.We can design the type and color of crusher according to customer demand. Give customers a better technology, installation and after-sales service.