News Date:2016-05-11 11:13:58

Divided by a ball mill grinding media: Forged steel ball mill and rod mill, ball mill structure is similar with rod mill, except that the rod grinding mill is more suitable for the expected size of 20-80 mesh ore grinding , such as beneficiation industry, sand industries. Why you need to choose a rod mill?

1, rod mill has less wearing parts and which replacement cycle is long, trouble-free operation for long periods, ensuring production efficiency. under normal circumstances, rod mill liners need to be replaced in 6-9 months , usually just regular steel bars can be added to the rod mill.

2, a uniform particle size, that is, without over crushed phenomenon, nor too large particle generation, it is ideal for metal and nonmetal mineral processing crushing.

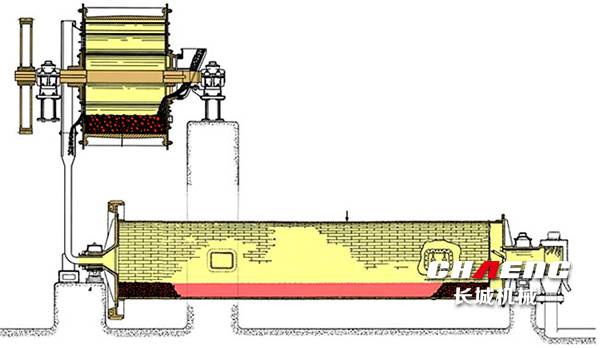

一, rod mill is mainly composed of cylinder body, feeding, discharging parts

Rod mill mainly consists of the following components:

1, cylinder body,: hole on the cylinder,for the repair and replacement of used barrel liner.

2, the feed section: used for feed.

3, the discharge portion: for use rod mill discharged qualified products.

Also it is include main bearing, transmission parts and so on. From the discharge form is divided into two kinds of material and the material surrounding the center, the Great Wall machinery can be as customer selection according to specific needs of customers, and the specific mining conditions.

二, how select a 600t/d rod mill ? what is the price?

Great Wall Machinery rod mill specifications are 1.5m * 3m, 2.1m * 3m, 3m * 4m, 3.2m * 4.8m, 4m * 6m etc., those can meet the needs of ore milling 300 tons -1500 tons per day! In addition, more than 30 t/h capacity , the Great Wall can be mechanical energy saving vertical roller mill, if you are interested, please click on the online customer service!