News Date:2015-12-08 10:14:49

High efficiency cement ball mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in chemical, metallurgy, and power industry and so on. This ball mill machine has increased the productivity greatly, the specific surface area is large, and it is new energy-saving grinding equipment, which has realized high capacity. Compared with internationally stipulated ball mill with same specifications, under the other situation of the same parameters, our cement ball mill output has increased by 20% per hour, and the power consumption has decreased by 10-15% per unit product. For open-circuit grinding, the specific surface area of cement can reach above 320㎡/kg. Besides, the performance of our cement ball mill has reached international advanced level, and it is suitable for close-circuit grinding, together with separator.

Two chamber mills are used for grinding slag, cement,and similar materials. They are typically arranged in a circuit with high efficiency separators. They grind materials up to 6500 cm2 /g according to Blaine. The mill is equipped with a lifting armoring in the first chamber with larger balls with a high comminuting effect. The second chamber is equipped with classifying armoring using smaller balls for finish grinding.

The partition diaphragm is equipped with a controllable material flow so that both chambers can maintain an optimum filling ratio. Raw Material from the second chamber is supplied to a separation circuit via an outlet wall. In case warmer materials are ground, water is sprayed into the second chamber or both chambers. In case the grinding circuit includes a roller press, single chamber mills with classifying armoring without a partition diaphragm are used.

How our cement ball mill work

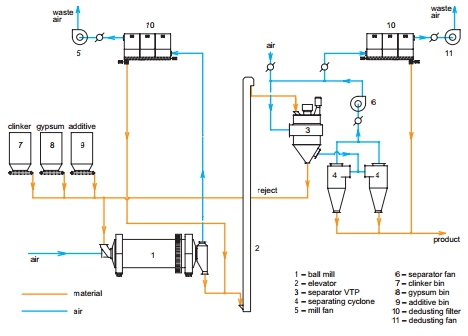

Our cement ball mill grinds cement clinker, gypsum and similar materials of moderate moisture content in a one compartment or two compartment systems. As the crushing compartments rotate, the balls inside them grind the clinker. Ball size determines finished product fineness.

Our cement ball mill can operate in an open or closed circuit; it has a corrugated lining in the grinding compartment for added effectiveness.

This cement ball mill consists of standard modules that can be configured for capacity, plant layout and end-product specifications. The drive can be fitted as a side or central drive upon request, and ball mills can be fitted with pre-grinders to achieve max grinding efficiency for any specified finish product quality. When fitted with the Hydraulic Roller Press as a pre-grinder, for example, the power consumption of the whole ball mill system can be reduced by up to 30%.

This cement ball mill is easy to operate and maintain, ensuring production efficiency and high ball mill running time. A large through-flow area facilitates the flow of venting air, which in turn ensures a low pressure drop across the mill and thus lower energy consumption

Main benefits of our cement ball mill

1. Highly reliable

2. Easy operation, easy maintenance

3. Wear-resistant parts – durable shell lining

4. Open or closed circuit operation

5. Grinds to any level of fineness

6. Energy efficient; large through-flow area ensures low pressure drop

7. Adapts to capacity, plant layout and end product