News Date:2015-12-04 10:03:59

In some of the countries, raw material like limestone is not available for manufacturing cement; they can import clinker, which is available in large quantity, and grind to produce cement. Clinker grinding plant is very simple. It comprises a feed hopper, Pre-crusher, Table feeders, Ball mill, Blending, Packing Plant and Material Handling equipment. Great wall can provide you clinker grinding equipment.

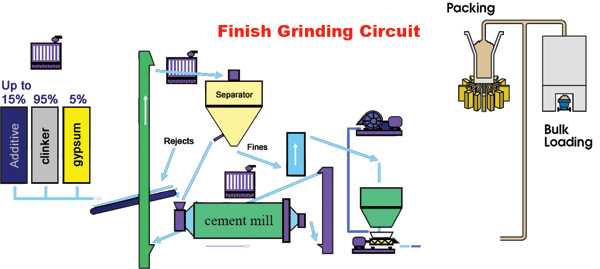

Clinker Process Flow Chart

1) Crusher and storage

The raw materials, Clinker and Gypsum are carried from stock yards by means of a Pay loader and charged into a dump hopper fitted with a vibro feeder to control feed rate. A belt conveyor handles material to Granulator for Crushing which is then stored with the help of a Bucket elevator into the respective Silos/Hoppers. The crushed material is then extracted by means of table feeders in the desired proportion and fed to the Ball Mill hopper.

2) Cement milling

The mix is handled by a Bucket Elevator and fed to the Ball mill hopper for intermediate storage. Where a mill feeder is installed, which controls the feed rate to mill, and desired fineness can be adjusted. The Cement produced is stored into the Cement Silo and blended through the aeration assemblies to ensure consistent and high quality Blended Cement.

3) Packing

Cement is extracted from the Cement silo by means of a screw feeder and transported to Packer Plant where it is first screened to remove any foreign particle than stored into a hopper for packing with the help of Auto Packers. Spillage if any during the packing is collected into a spillage hopper and recycled to the system. The packed bags are handled by a Belt conveyor and transported to Cement Godown for sale.